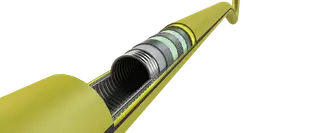

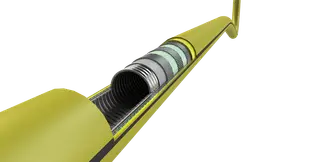

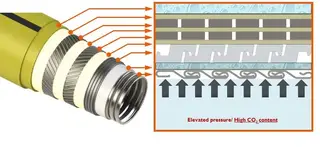

The flexibility of these lines results from its multilayer structure composed of metallic and polymeric materials. It is known today that it is possible that the permeation of gases, namely CO2, occurs through the structural layers that constitute a flexible line. The mixture of CO2 with condensed water or sea water creates an extremely corrosive environment in the space between layers which may, together with the loads to which these equipment are subject in operation, lead to the rupture of the lines by the phenomenona identified as Stress Corrosion Cracking by CO2 (SCC-CO2).

Typical flexible pipe

Since the riser rupture incident in January 2017, Galp / Petrogal has been working with Petrobras and other partners in order to find possible short, medium and long-term measures to solve this extremely complex situation. One of the measures underway to mitigate this problem in a long-term is the complete understanding of the Stress Corrosion Cracking by CO2 (SCC-CO2) phenomenona and the development of new methodologies, in order to estimate accurately the levels of corrosion and to anticipate integrity issues of the flexible pipes.

This innovative project signed recently by Galp / Petrogal will last 50 months. During this period, the metal and polymer layers of real scale flexible line samples will be tested by the Brazilian company Símeros and by the SENAI Institute both specialized in the study of these materials.